What is Tolerance & Why is it needed? A certain amount of tolerance or allowance for a specific variation in the size and geometry of a part or feature is necessary. No process or machine is perfect! Each process or machine has its’ own variation in its repeatability and reproducibility. Every part is unique and it is impossible to produce the same part over and over again perfectly. There are measurable differences in every part, and because of this product design must be robust enough to accommodate the variation. Specifying tolerances is a way to make the parts close to perfect.

When does Tolerances become important?

–Variation in the process or machine is inevitable, so acceptable variation must be specified in the drawing by using tolerance stack-up analysis. –Variation affect the functionality of the part & cost in terms of precise manufacturing, inspection and the rejection of parts. –Assemblies : Parts will often not fit together if their dimensions do not fall within a certain range of values. –Cost of manufacturing: Most of the time designers play it safe by giving very tight tolerance which in the end can rack up huge manufacturing costs. –Interchangeability : If a replacement part is used it must be a duplicate of the original part within certain limits of deviation. -The relationship between functionality and size or shape of an object varies from part to part.

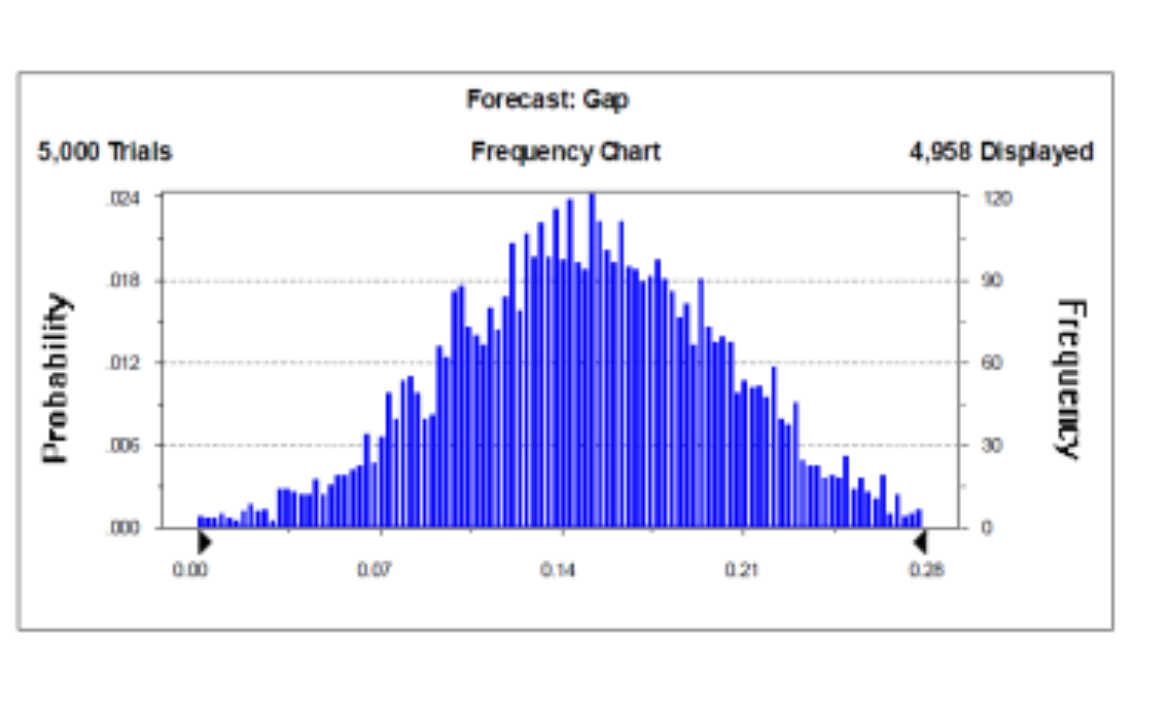

What is good enough? Loose tolerances leads to assembly interference and unintended functionality and discomfort by the end users. Tolerance analysis will determine the optimized fit and tolerance for a part or feature. Tolerance analysis is conducted in all CTQ (critical to quality) parameters well in advance during product development and is communicated in the manufacturing drawings preferably using ASTM Y14.5-2009 GD&T standard which best industry practice in the world.

Kohlex engineers are Six Sigma green belt certified from GE and they have experience in conducting tolerance analysis using Crystal Ball, Minitab, SolidWorks and hand calculations.

OUR CAPABILITIES

Concept Generation

"Imagination is everything. It is the preview of life’s coming attractions.” -Albert Einstein All great achievements begin with an idea. But an idea not properly developed will [...]

3D Modeling

"Words are only painted fire; a look is the fire itself". -Mark Twain Why do you need a 3D model? Why conventional 2D drawings just isn’t enough? While 2D drawings tell the [...]

Product Design

"Our environment, the world in which we live and work, is a mirror of our attitudes and expectations". -Earl Nightingale Excellent product design requires both the practical knowledge of [...]

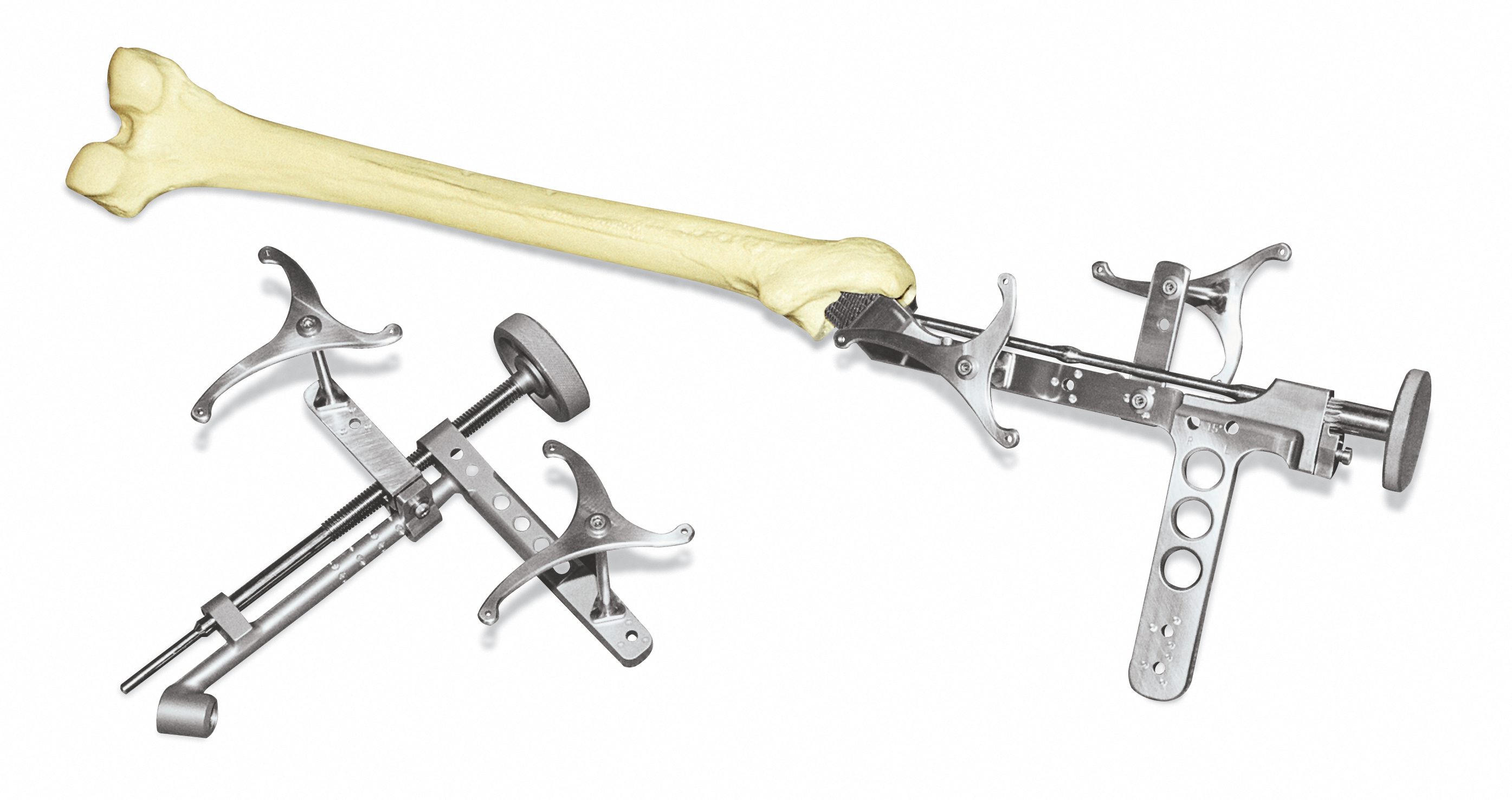

QARA Services

We offer various services for medical device organizations to make the products and services better and complaint to requirements. Quality Management System - - ISO13485:2016 consultance and system gap assessment - [...]

Prototyping & Testing

It’s one of the critical steps among the product development in which people will be disappointed about the results Teams will be counted on their debuts Over spend of money than [...]

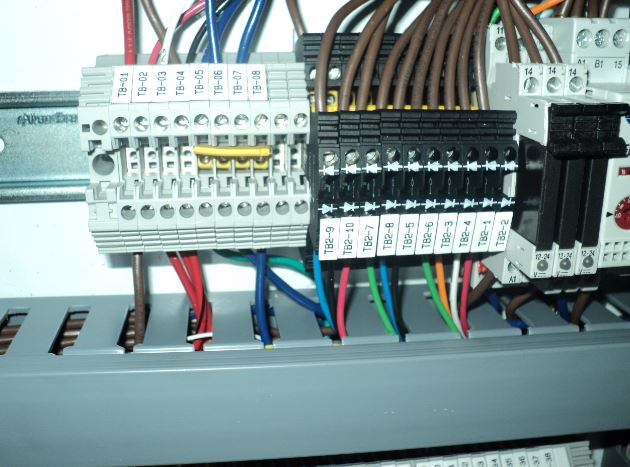

Hydraulic Design

Do you find Advantages changing to Hydraulics from your existing system? Do you had a requirements for setting up a new hydraulic system ? Do you have any problems with the existing [...]