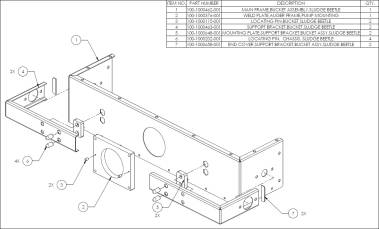

Concept Generation

"Imagination is everything. It is the preview of life’s coming attractions.” -Albert Einstein All great achievements begin with an idea. But an idea not properly developed will remain just an idea. At Kohlex we have experience in taking ideas and building them from concept to production. We [...]