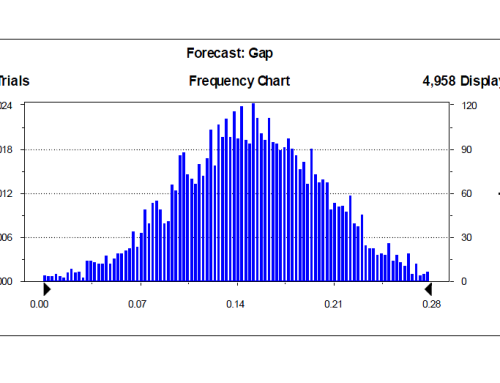

Are your products optimized for better Factor of Safety (FOS)?

In general, most products are over designed due to lack of predictive engineering knowledge. Over design will cost 2 to 3 times more than the original cost. On the flip side, products that are under designed can lead to reliability issues and customer dissatisfaction. Applying predictive engineering in the early stages of a products development avoids trial and error methods and allows for the product to be manufactured quicker.

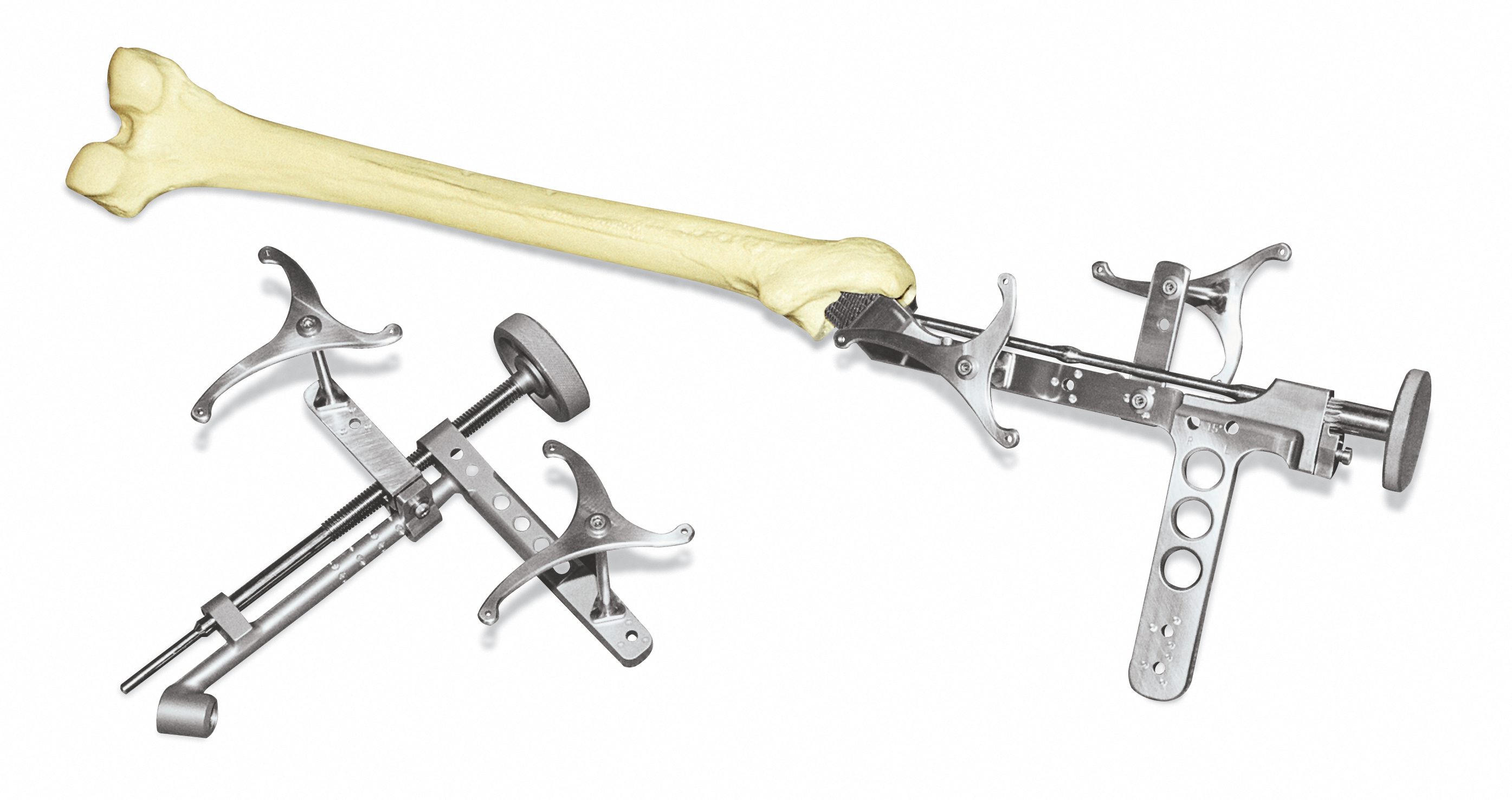

Our engineers have experience in converting your requirements into boundary conditions and loads. We know how to break the assembly into small objects to optimize the problem by using FEA, good at deciding FOS for your application, element type, size, and meshing methods etc.

Understanding the requirements and converting them into adoptable loads and boundary conditions is the key to success in structural analysis. Our vast experience in FEA analysis (Static, Dynamic, Motion Simulations, etc.) will help you get your structural simulations with ease to optimize your designs and avoid premature failure.

Invalid Displayed Gallery

OUR CAPABILITIES

Concept Generation

"Imagination is everything. It is the preview of life’s coming attractions.” -Albert Einstein All great achievements begin with an idea. But an idea not properly developed will [...]

3D Modeling

"Words are only painted fire; a look is the fire itself". -Mark Twain Why do you need a 3D model? Why conventional 2D drawings just isn’t enough? While 2D drawings tell the [...]

Product Design

"Our environment, the world in which we live and work, is a mirror of our attitudes and expectations". -Earl Nightingale Excellent product design requires both the practical knowledge of [...]

QARA Services

We offer various services for medical device organizations to make the products and services better and complaint to requirements. Quality Management System - - ISO13485:2016 consultance and system gap assessment - [...]

Prototyping & Testing

It’s one of the critical steps among the product development in which people will be disappointed about the results Teams will be counted on their debuts Over spend of money than [...]

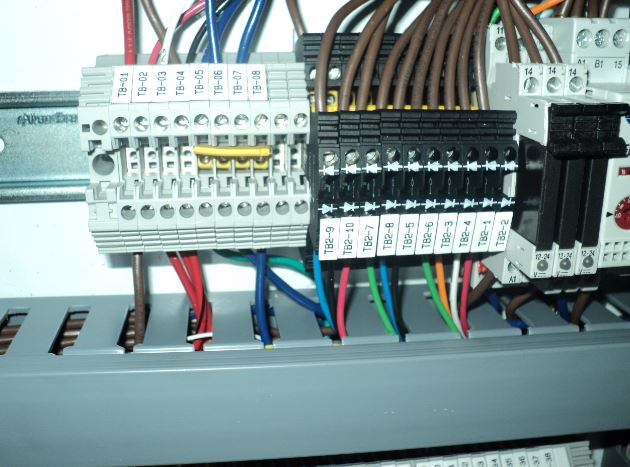

Hydraulic Design

Do you find Advantages changing to Hydraulics from your existing system? Do you had a requirements for setting up a new hydraulic system ? Do you have any problems with the existing [...]