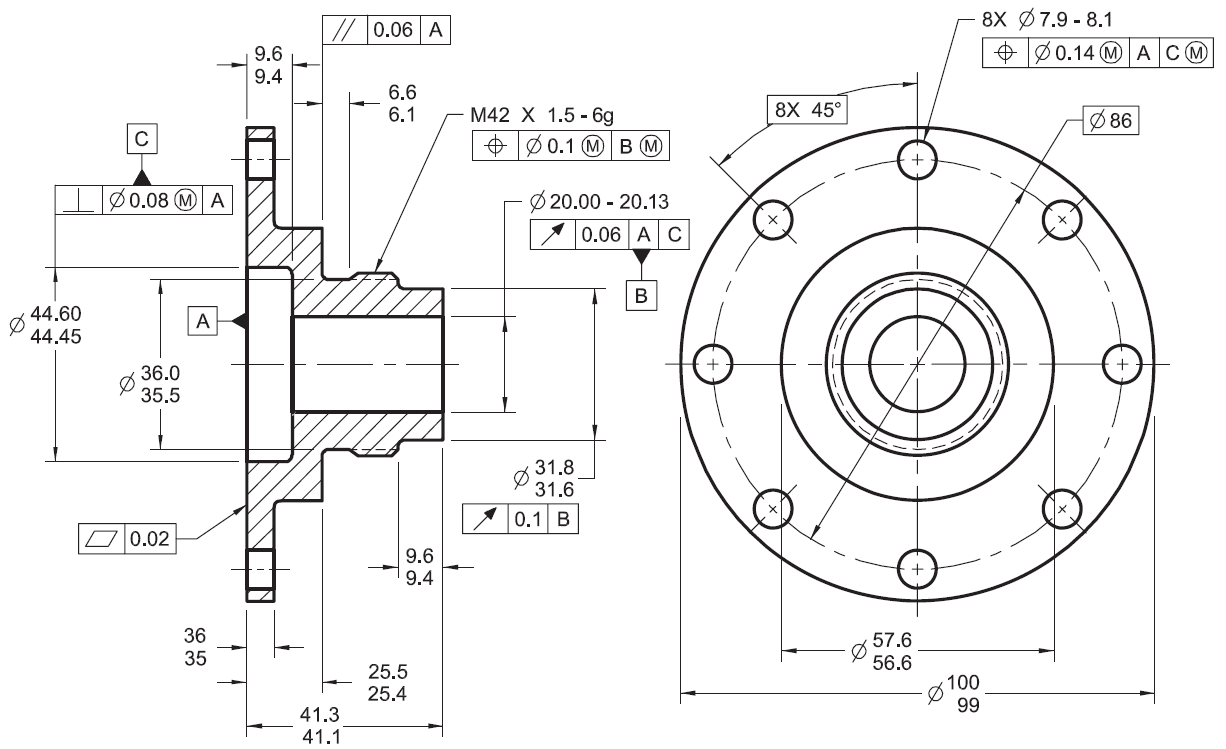

An Engineering drawing cannot be complete without GD&T. Most of the companies in United States and around the world use GD&T in their drawings. Kohlex engineers are experts in GD&T and can implement GD&T in your design and drawings. We also offer GD&T training to your Engineering, Production and Quality team members for effective implementation and usage of GD&T throughout your organization.

What is GD&T?

GD&T stands for Geometric Dimensioning and Tolerancing, as defined by ASME Y14.5M-1994.

GD&T: An International Language

Geometric dimensioning and tolerancing is an international language used in drawings to accurately describe a part or assembly. The language consists of a well-defined set of symbols, rules, definitions, and conventions that can be used to describe the size, form, orientation, and location tolerances of part features.

Click on the first image to play slideshow. During slideshow you can click on right or left side of the image to go to next or previous images respectively.

Why GD&T?

Why GD&T?

When GD&T is properly applied and understood, product costs go down because:

- Engineering can accurately define what is required. This can cut down time taken to interpret the requirements by 25%.

- Inspection setups are not subject to interpretation. The lack of trial-and-error may save 40% in gage cost.

- Everyone can do their jobs right the first time, resulting in as much as 25% less Material Review Board action.

- Datum systems speed up manufacturing and inspection and provide an effective basis for SPC.

- Tolerance bonus will pass as much as 20% more parts through inspection that would otherwise be rejected.

- Accumulated benefits of GD&T often enable lower and more accurate cost estimates for fabrication.

An Engineering drawing cannot be complete with out GD&T. Most of the companies in United States and around the world use GD&T in their drawings.Kohlex Engineers are Expert in GD&T. Our Engineers can implement GD&T in your design and Drawings. Also we offer GD&T training to your Engineering, Production and Quality team members for effective implementation and usage of GD&T throughout your organization.

Invalid Displayed Gallery

OUR CAPABILITIES

Concept Generation

"Imagination is everything. It is the preview of life’s coming attractions.” -Albert Einstein All great achievements begin with an idea. But an idea not properly developed will [...]

3D Modeling

"Words are only painted fire; a look is the fire itself". -Mark Twain Why do you need a 3D model? Why conventional 2D drawings just isn’t enough? While 2D drawings tell the [...]

Product Design

"Our environment, the world in which we live and work, is a mirror of our attitudes and expectations". -Earl Nightingale Excellent product design requires both the practical knowledge of [...]

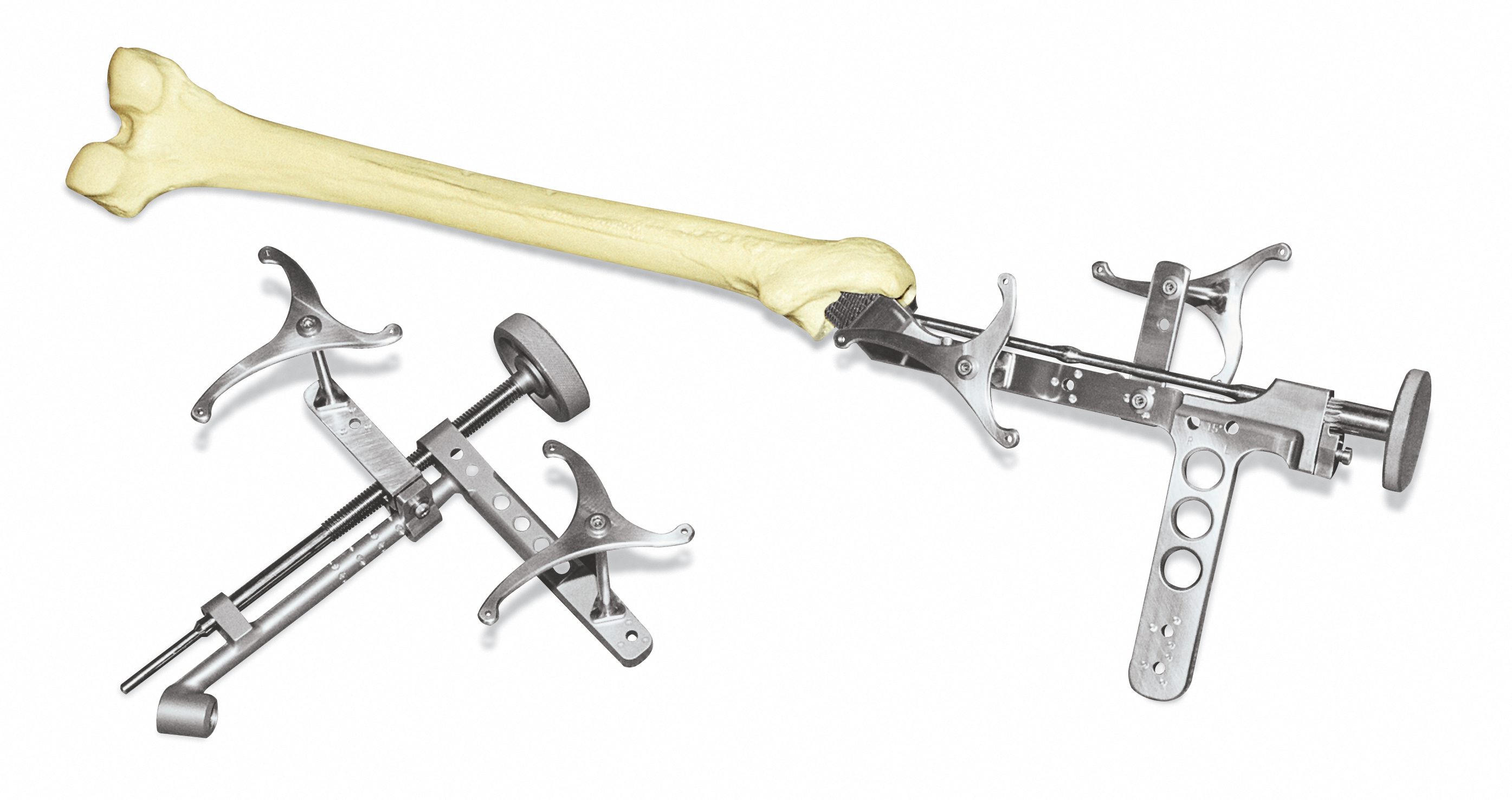

QARA Services

We offer various services for medical device organizations to make the products and services better and complaint to requirements. Quality Management System - - ISO13485:2016 consultance and system gap assessment - [...]

Prototyping & Testing

It’s one of the critical steps among the product development in which people will be disappointed about the results Teams will be counted on their debuts Over spend of money than [...]

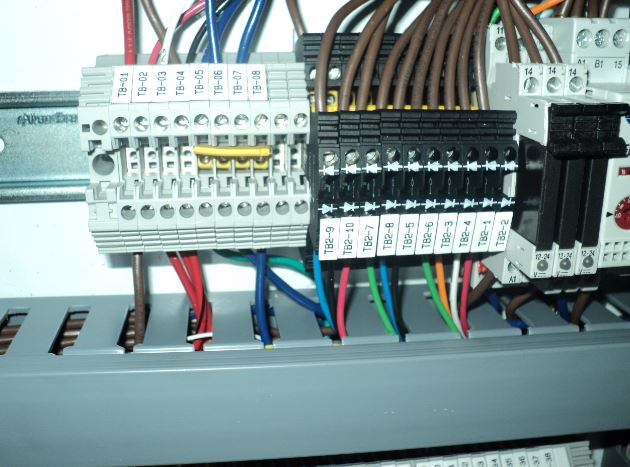

Hydraulic Design

Do you find Advantages changing to Hydraulics from your existing system? Do you had a requirements for setting up a new hydraulic system ? Do you have any problems with the existing [...]